First want to thank Ed French from polygno.com for letting me borrow from his site.

Every hotend and extruder combination has a capacity to melt and deposit a certain volume of filament every second. If you push your printer above that limit you will get underextrusion as well as poor layer adhesion.

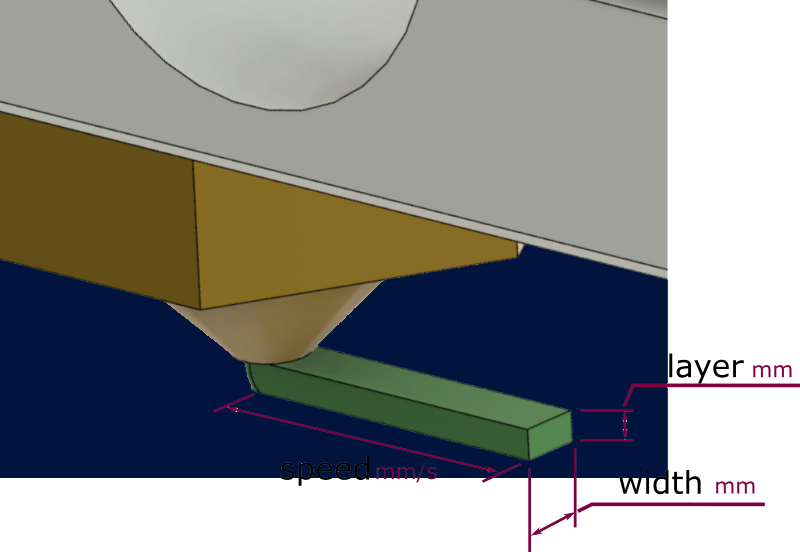

You can check you slicer parameters using this calculator to make sure you avoid this limit.

For most 40W heater-based hot-ends, with good extruders, should see c. 10-17(mm)3/s. This is typical for most printers as purchased. A volcano-type is closer to 20-30(mm)3/s , whilst E3D claim 110(mm)3/s for their super volcano.

Remember, the width of the track is usually the same as the nozzle diameter, although it is often better to print a wider track if you want improved mechanical performance (e.g. printing a 0.6mm track from a 0.4mm nozzle).