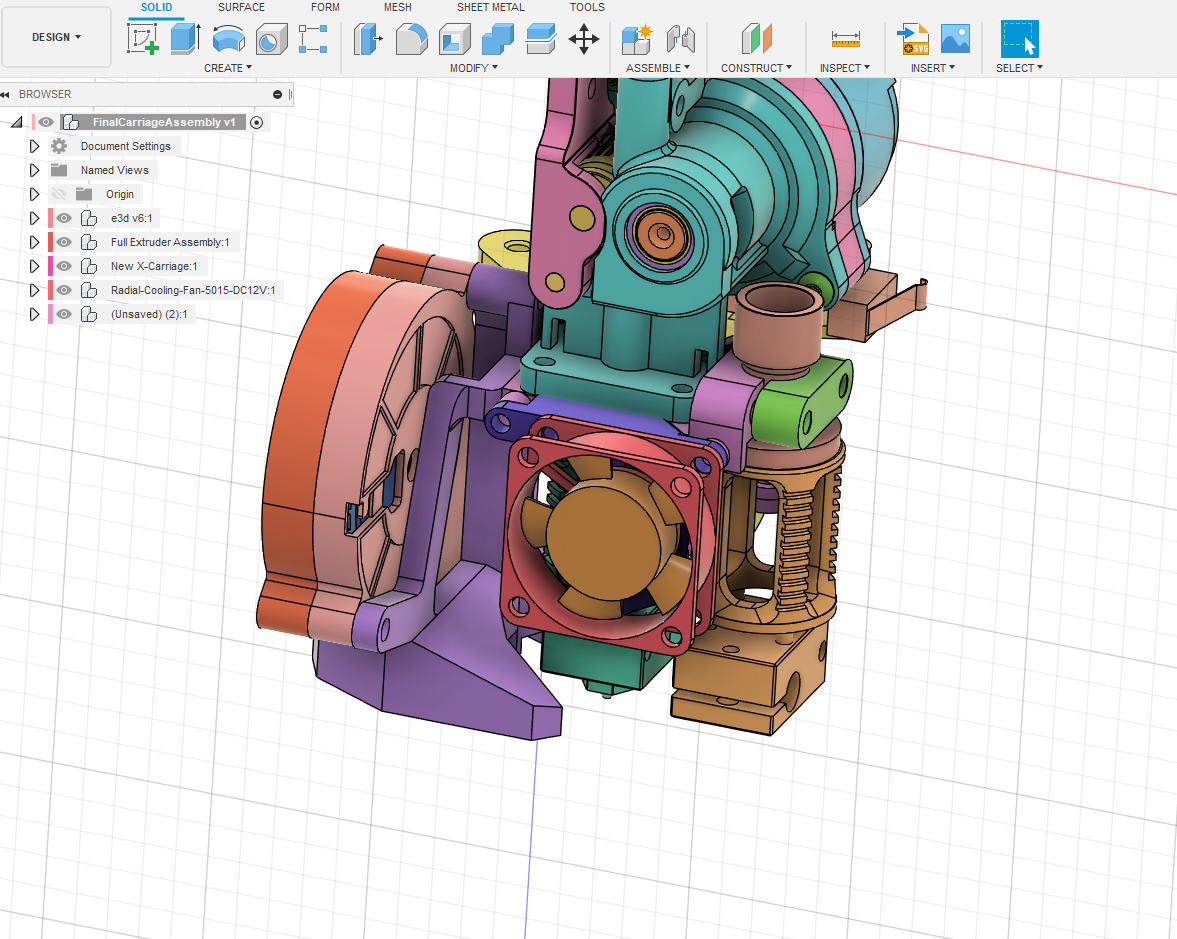

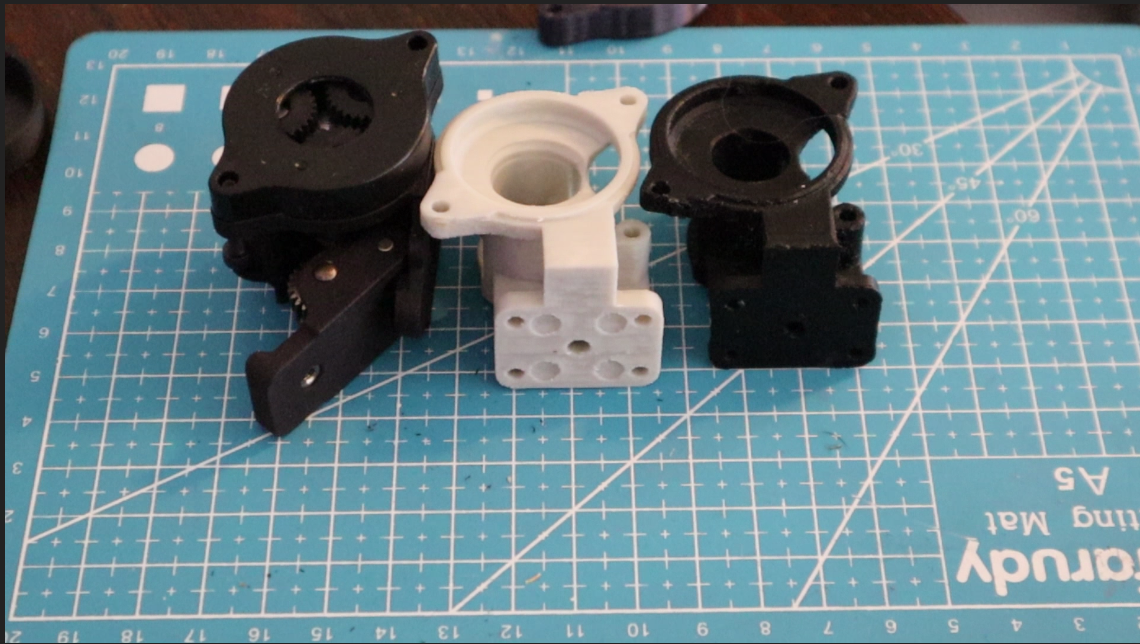

Jake allen redrew my last version adn tehn me and him tweaked it until no end and it is really the ultimate iteration at this point. Their is 2 versions here these are meant to work with the ldo and origianl bom size bearings “14mm” i am testing the vivedino 16f front bearing version and will add that shortly

Fix your install if update broke it

HELP, Klipper update broke my install!

This is a quick guide to show how to fix your install, if a new update caused a version mismatch.

There are pretty standard guides, but most leave out that with input shaping and other advanced features, we have to also compile the microcode for the host controller, a raspberry pi in most cases. I may be adding a guide to use a tablet as the Klipper host in future, so that we could use an old tablet to control the printer, and just use the Duet spi bus, so we could mount a nice big tablet or old laptop, etc, onto the printer and have it complete standalone. Below is a list of commands to use for anyone feeling a little overwhelmed, but it’s much cleaner to follow this video.

Tips:

- To enter a previously entered command, press ↑ on your keyboard. You can cycle between options with ↑ and ↓

- To copy text inside a PuTTY terminal, just select it.

- To paste, right click

Directions:

- Open PuTTY, and connect to the raspberry pi with your IP address. (mac can use the ssh command)

- Login to your pi, default is pi and raspberry

- Enter

cd klipper - Enter make clean

- Enter

make menuconfig - Select

Micro-controller Architecture - Select

SAM3/SAM4 (Due and Duet) - Select

SAM4e8e (Duet Wifi/Eth)insideProcessor Model - Ensure that

(USB)is selected insideCommunication interface - Press Esc then Y

- Enter

make - Enter

sudo service klipper stop, enter your password - Enter

ls /dev/serial/by-id/* - Copy the serial by just selecting it in the window

- Enter

make flash FLASH_DEVICE=and paste your serial after the = - Note their is a chance that flash may fail and usually this will place the board into a bootloader mode like original install does when you hit the erase pins. If this occurs please rerun ls /dev/serial/by-id/* so that you can get the correct serial and use this one repeating step 10

- Enter make clean

- Enter make menuconfig

- Select

linux processinsideMicro-controller Architecturepress Esc then Y - Enter make

- Enter make flash, enter your password

- Restart the klipper service in the mainsail interface

History added to mainsail

ocotoprint image

I am compressing and uploading working octo mainsail combo image

https://drive.google.com/file/d/1xoEdAjmwvyE0juGYF3OcGip45cIBtuxF/view?usp=drivesdk

upload folder moved

EDIT. Hoe to find your folder

You guys own the folder but it doesn’t show in your shared with me since it’s yours so you need either search your name or owned by me on the search bar. So what you do “Sean greenes idea” is you search your name on Google drive and then right click and set it to starred so now it will show on left next to all the shortcuts. You could always make a shortcut somewhere on the computer to but this is the easiest solution.

I moved the folders to a parent directory so no one else can see your folder anymore. When you join you send me message with your email you use for gdrive or gmail and i will add you to the gdrive and also make you an editor of the public uploads. Then you make a folder so you are the owner and it just uses my storage and gives me access then i will move it to the parent directory so it becomes private.

Also this is the folder for all orders https://drive.google.com/drive/folders/1STfh0rq-oGkIZJ0GV1mgppjR7uyA2wmV?usp=sharing

so you make a file with your order no personal info just your order and i can let you knwo progress in the text file and then when its done we delete it. This way your address and stuff go in the private folder but the orders are all right in one place for me so i dont miss any by accident. This will be until the webstore is working

Gantry upgrade update and background

A few months ago, I got the idea for a dual extrusion setup that would reuse a lot of the stock components, and talked to Tom Jones and a few others about it. I also had been working on cable chain modifications and fixing the printer’s other shortcomings. The dual extruder got put on hold because the stock Troodon board was limiting.

I focused on Klipper and RRF3 while trying simplify things, to improve prints. I was able to get amazing prints, but it took excessive calibration and attention to detail. Most troublesome was the constant required attention. The main issue was the cable chain, which then magnified other issues, such as the play in the guide. This is all because of a few things, including partially user error due to lack of instructions. The stock setup has a long moment arm and adding the DDE (direct drive extruder) increases the slop, “depending on other factors anywhere from a little to a very large amount that manifests as banding and ugly walls.” So, fast forward I figured out Klipper and got RRF3 working properly, and during this I tried over 500 dollars in rails from Amazon and AliExpress to Hiwinn, Ldo and THK. I found that no matter what, if I lifted the cable chain by hand, I could measure close to a millimeter of deviation with a laser attached to the hotend. So I then talked to Tom Jones again, and this time felt I would be able to figure the control scheme out for the second extruder, without replacing the board. I also had been running my stock rail on it’s side. We proceeded to design a gantry upgrade that incorporated the New 2.4 belt path that I had been running a version of, with a floating rail to reduce weight. Also we stepped up the size of the rail to increase accuracy at the same time. My main goals were that I wanted to not lose build space, and I wanted to have the dual hotends weigh close to or less than the stock . We achieved the goal, but we still had the crap cable chain.

Now Jake Allen was back to the group as “He bought a Troodon since he previously had one at work, but then no longer had access so he had stepped back.” He wanted to collaborate, so we sent him everything and I started working with Jake and Tom at the same time. However, we had different goals in mind. He wanted “modular with single hotend”. So early on, he asked what guidelines I wanted him to adhere to, so I told him to just keep everything somewhat compatible with each other, and try to minimize weight and loss of build area. It quickly became apparent that it could not happen that way, with a modular design, so I said, “let’s just continue developing both and figure it out,” but every time we updated the mounts or design, Jake incorporated it into his. Around this time, Tom got much busier and I said I need to just do the cable chain, since it is stupid to do this in two steps, it would be waste of work and money. Jake then made a parametric version of the Panzer chain, and I worked out a path and hacked some mounts together. I was able to get it up and running after a few iterations, which proved the wires were long enough if we were creative. Jake then helped me clean up the files and kept teaching me more CAD tricks and commands. So now we had two viable designs. One was a mosquito-centric, but dragon compatible, single hotend setup that could support two fans and a second hotend on the front. This was a jack of all trades, but it was heavier and you would lose around 35-y off each hotend. If you needed to use the supports for the full print, it would lose a lot. I was worried about the plastic mount for the hotend, but it seemed good for someone not really planning on using dual extrusion except occasionally. The original design at this point was able to run dual extruders, with no loss of travel on the main hotend, and 5 to 10 x less with the second hotend. However, it could not support 2 fans and the parts were not modular, “Meaning, a fan duct for one side could not just be mirrored and mount on the other,” but I felt that if I am printing the parts for add-ons, it doesn’t matter to me if I have to design different hole patterns for different sizes. So it was now where one design did what it did better, but the other did more things. So as always, it was either more flexible, or better performance with less options. We had tried the dual setup with Jake’s side by side, but it had to be spaced really wide and it seemed not viable.

We kept working and Jake has had nothing but bad luck with his genuine Mosquito, so he said, “I am done, I’ll just go dragon, we can just do yours and Tom’s for everything.” I hated the way he sounded, as I knew he was bothered. In past I have talked to Tom, and was just talking to Theodor Lasenko the other day, where I mocked it up on a screenshare with the hotends turned 90 degrees. Turned out, the mosquito could mount just as close as the dragons. Funnily enough, Jake had just turned the hotend 90 degrees on his mount too. Then the last thing happened, which was that Berd-Air become viable. A lot have posted online having loud noise, and bad performance but after a lot of testing I found settings for the pump that are great, and between that and a few other tricks, I can print 85 degree overhang with Berd-Air. So end result is that Jake has decided to just jump back over, and we will add mounting holes for a mosquito so now its one design that makes it cheaper for all and just is simpler in many ways. It’s already daunting having a fan duct, a Berd-Air mount, two types cable chains (stock and Voron style), two BLTouch mounts, etc, so we finally are ready to take a tally for orders and place the order. I am working on a full bill of materials, so I can figure out what the upgrade actually costs when all the bolts, etc, is accounted for, because I have tried a lot of different things to arrive at the final bill of materials. Also I have about 30 hrs in on last mounts and 20 hrs in on the newest cable chain brackets with optical endstop, and it seems rock solid.

I am also making some more changes to the orbiter for ease of printing and to it mount better.

New PA tool

well i decided to take crash course in javascript and i ripped the marlin generator source code and changed it for klipper and rrf so i made two versions that are native for the troodon or railcore or voron and reall can work for most printers on klipper or rrf . It is under the tools tab on the website. Advanced3dprinting.cohttps://www.advanced3dprinting.com/tools/

Patrons make sure to send me your gmail when joining

This is a cool easy way to tune your pressure advance on rrf and klipper

Pressure Advance: The Easy Way, “Just use the new tool”

Linear Advance Calibration Pattern | Marlin Firmware (marlinfw.org)

The tools tab now has native generators on it.

This is a basic guide on making a PA (Pressure Advance) gcode file. I plan on forking the code and changing it to natively generate the gcode for RRF and Klipper, but it’s easy, so I am not making that a priority. Just use the above-linked tools.

- Generate the gcode for marlin inputting your settings for the filament and nozzle you are using. You want .005 steps ranging from 0 to .1 for most nozzles and filaments. If your filament is very soft or your nozzle is small, then .2 may be better as a maximum value.

- Add a G32 after the G28 in the side panel.

- Add a T2000 after the P500 on the acceleration line.

- Download and open in notepad, or some other simple editor that does not format text.

- Use find and replace to find M900 K and replace it with the respective values:

- Klipper is SET_PRESSURE_ADVANCE ADVANCE=

- RRF is M572 D0 S

- Save the file, making sure the extension is .gcode.

- Upload to the printer and print.

- Find the line that stays most uniform at the speed changes marked by the top two vertical lines.

- Enter the corresponding value in your slicer’s filament gcode override. If slicer does not have that, then enter it into your start code and name that profile for the filament you calibrated.

I found some cool diagrams that show the improvements with Klipper pressure advance compared to regular Linear Advance (LA) and PA with the smooth pressure advance algorithm. With direct drive, it does not matter as much, but with Bowden and high values, Marlin and RRF have a hard time keeping up and end up slowing the print a lot to maintain the max acceleration for the extruder in firmware. So, a stock 300 really needs 1.9 and that doubles print times on RRF. With Klipper, it is not a problem and it does not reduce the acceleration as the extruder hits its ceiling. Instead, it smooths out the max values and extends them slightly to the same end result. You can configure the smoothing time if you really are pushing things, but the stock value is adequate. We do not want to reach the point where we start reducing the effectiveness of the pressure advance. This all is not important if running direct drive since we rarely need more than .1 seconds of Pressure Advance with the Orbiter or most other high-end solutions. I just figured it would be interesting to give some background on what is happening under the hood.

Klipper kit install instructions

These are the install instructions by Alex Or. He has done all of us a huge favour. I will be sending this to anyone who purchases a harness or kit, this will also be available to my patrons.

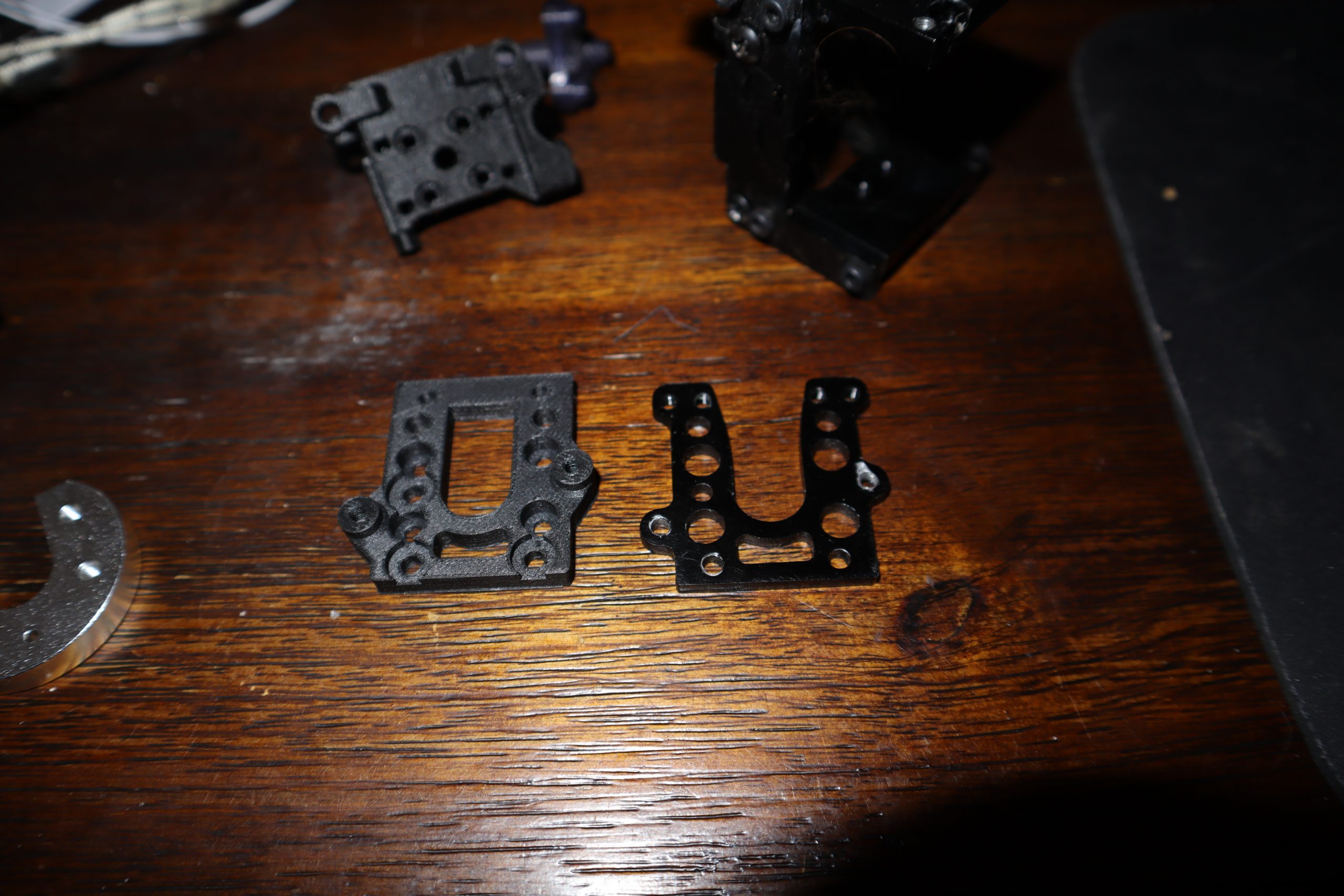

DDE Plate, and why you need it

The DDE (Direct Drive Extruder) kit is one of the most important upgrades for your Troodon’s if you want to be serious about performance and reliability. However, this does not mean it is perfect. The stock plate mounts with only 3 bolts that are heavily leveraged against as shown in following video.

The STL for the upgrade plate is available for download using the link below.

https://drive.google.com/file/d/12Kvd5OL-qsA94Lqb9yHYOjGK3acGJ8lc/view?usp=sharing

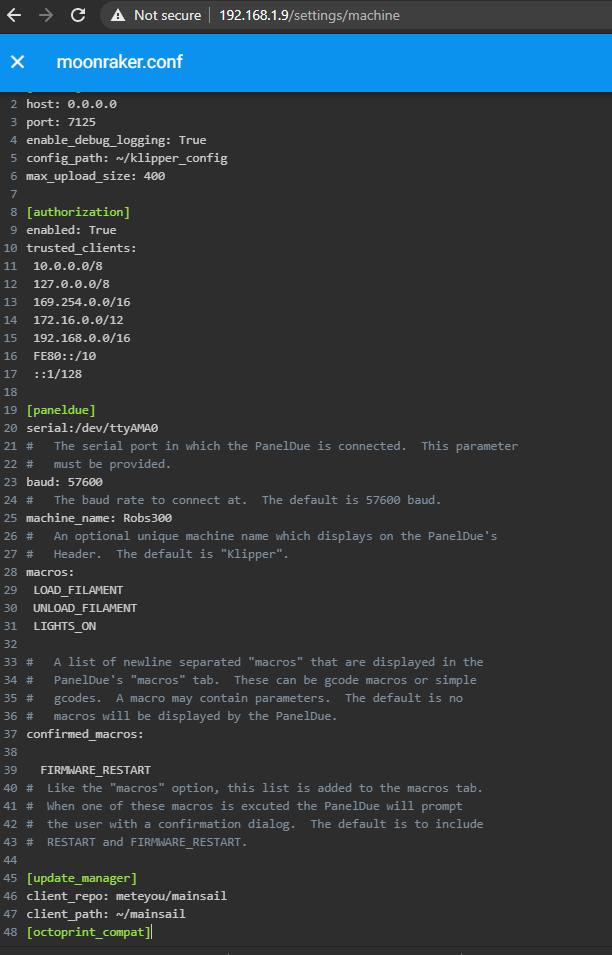

Newest Klipper Mainsail update changes!

Klipper newest mainsail update (moonrakerv0.41-12 or newer) requires the following line to be added:

[octoprint_compat]Just paste it in the bottom of your moonraker.conf file as shown below.

You will find this in the Settings > Machine tab.

Orbiter modded by me

I added one designed to work with the vivedino front bearing.

only need the housing and latch if converting a dde . i included diff latch alignments cause i found that some diff clone gears are slightly diff length

Klipper guide for flashing and install

Alex Or is helping by putting a lot of my pictures and information together into a presentation. It should be ready soon, he had me review his draft. We are making a few changes, but it looks great already. It is time to make a video of the flashing procedure, so Jake Allen installed a new board and let me record a remote session of me flashing it for him.

Here is a video showing the basic harness install.

Holger asked for a picture of the pi camera mounting location.

Klipper harness install

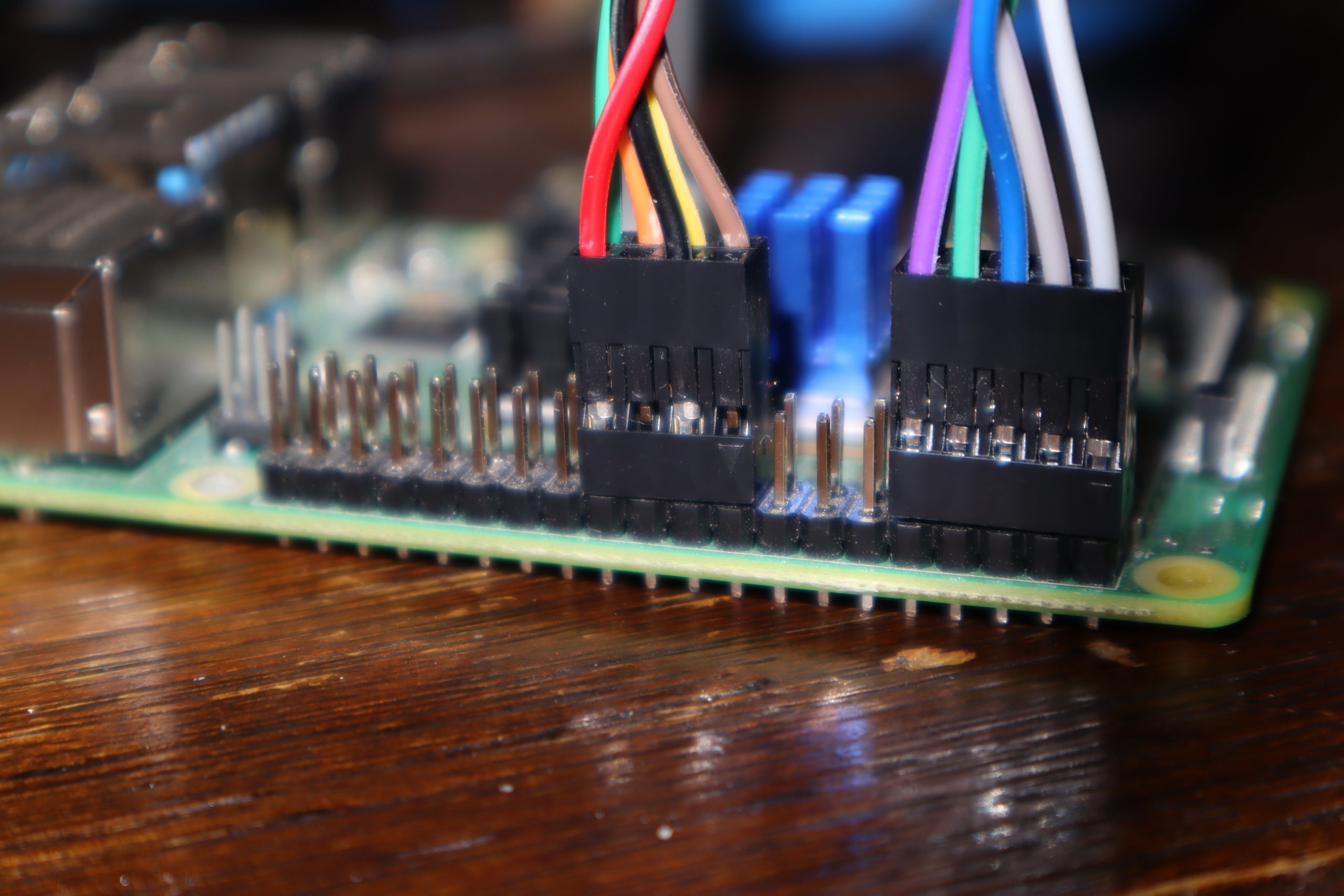

The klipper harness is assembled with the intent of using the small triangles on the harness to locate the pins.

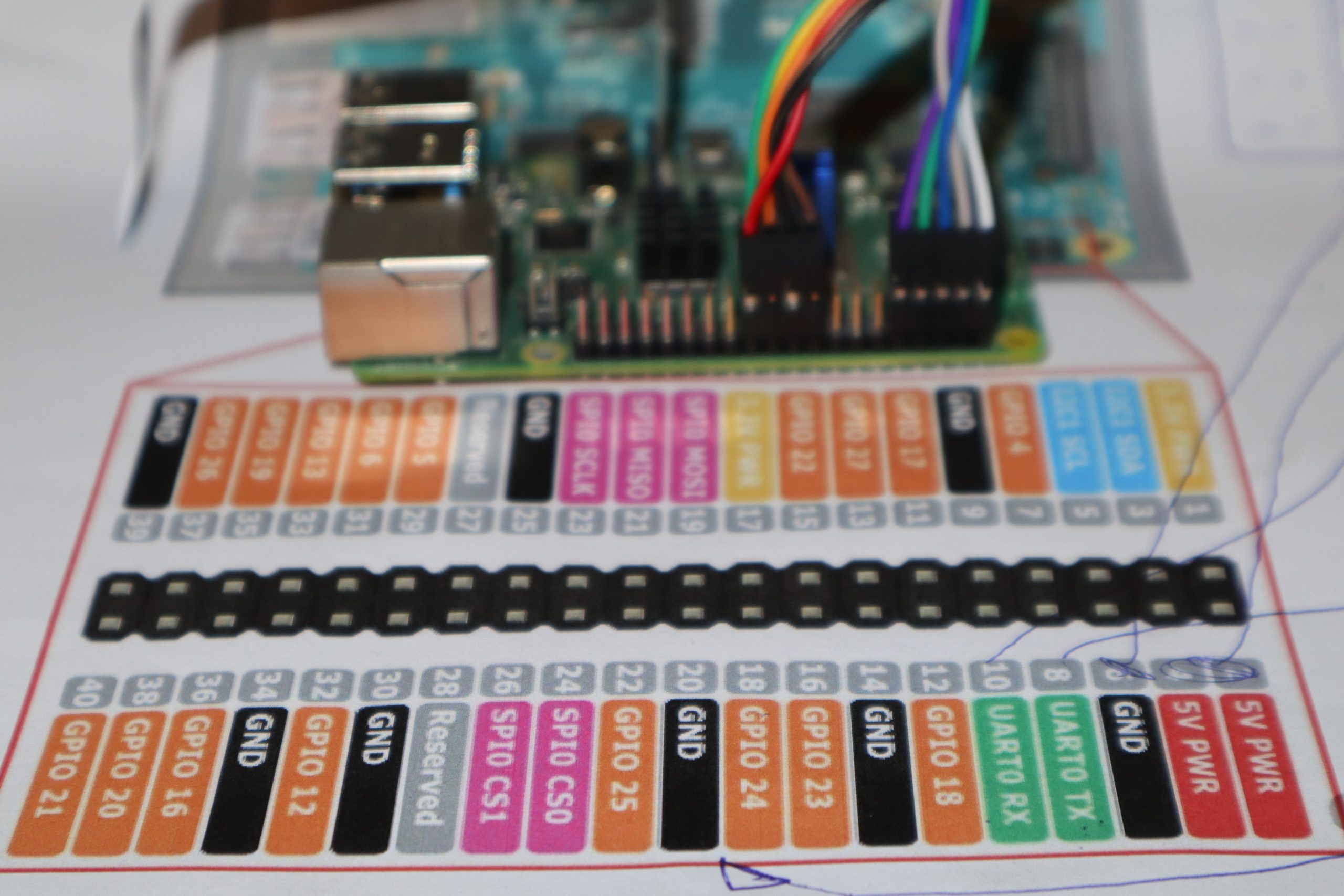

A rpi diagram courtesy of raspberrypi.org shows the pin numbers here

The harness comes with a diagram and shows the pin numbers. The main harness, the connector on the right in the below image, has the pin marked with a triangle go to pin number 2.

The harness connector on the left is for the accelerometer, and is not needed for the main install.

Connect the Panel Due harness in the manner that is described in the video below. Be careful of the orientation of the Panel Due plug you remove, and connect the power wires as described.

One of my Patreons is working on a presentation documenting the install, so I will add it when it is ready.

Patreon logins are live

Easy weight reduction

The stock setup has a groove mount plate and an assembly that is just too heavy. As much as it is better than a lot of other groove mount implementations, I see that it can be made better.

This are the dragon mount and the 5015 fan shroud download links.

https://drive.google.com/file/d/1BtnqhWhkixEPdtRQnBg3gijz13YyvnBc/view?usp=sharing

https://drive.google.com/file/d/1qeLU5dZkYZxnouUQ3TwafIUh0kFKA1pV/view?usp=sharing

I do have stock fan shrouds too, but I think I have to adjust the height to work with the dragon and other short hotends, as I have modified these for someone with a stock setup when I first got the printer.

Unlock with Patreon

Unlock with Patreon